About Me

Excel VB Programming (VB6)

Excel Spreadsheet Formulas

Excel VB.NET Programming

Access Programming (2003)

Lean Six Sigma Methods and Tools Used

Below are the sets of tools being utilized in Six Sigma methodologies.|

Brainstorming Tools

Process Mapping Tools

Root-Cause Analysis Tools

Risk Analysis Tools |

Data Gathering Tools

Process Planning Tools

Advanced Analytical Tools

|

Strategic Planning Tools

Statistical Analysis Tools |

Process Control Tools

Other Tools & Techniques |

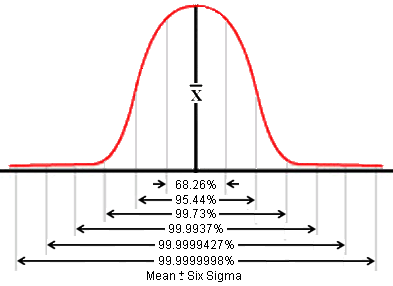

In statistical terms, the purpose of Six Sigma is to reduce process variation so that virtually all the products or services meet or exceed customer expectations. This is defined as being only 3.4 defects per one million opportunities (DPMO).

|

|||||

| Process Sigma | DPMO | Long Term Yield % (i.e. percentage of successful outputs | |||

| 1 | 691,462 | 30.9 | |||

| 2 | 308,538 | 69.1 | |||

| 3 | 66,807 | 93.3 | |||

| 4 | 6,210 | 99.4 | |||

| 5 | 233 | 99.98 | |||

| 6 | 3.4 | 99.99966 | |||

| Figure 1.1 One to Six Sigma areas under Normal Curve |

Table 1.1 One to Six Sigma conversion table |

||||

How to calculate DPMO, Defects Percentage and Process Yield?

DPMO = (total no. defects / total no. of process opportunities) x

1,000,000

Defects Percentage = (total no. defects /

total no. of process opportunities) x 100

Process Yield = (100 - defects Percentage)%

Assuming there are 220 defects per million and a shift of 1.5 for all values of z. In Excel, you type as:

NORMSINV [1 - (220/1,000,000)] + 1.5 = 5 sigma or 5.02

Six Sigma was developed by Motorola in 1980s, but today Six Sigma comprises lots of things and has many meanings over time. In different terms, Six Sigma is:

-

a metric, a business development methodology, a management system, and all three at the same time.

-

a data-driven and statistical analysis method that can measure and improve any element of production activities and customers services, with a focus on customer impact.

-

a process that structures work into Project Charters that clearly define the project goals and potential benefits which are directly link to strategic critical success factors, customer value and bottom line results.

At the heart of the Six Sigma are two methodologies - the DMAIC model for problem solving and process improvement, and the DMADV model for creating new product designs or process designs in such a way that it results in a more predictable and defect-free performance.

DMAIC stands for:

-

Define the problem, customer requirements, business goals and objectives, team roles and responsibilities, scope and resources, processes, and performance baselines.

-

Measure the problem or processes (variations, defects per unit, defects per million opportunities, and the yield percentage).

-

Analyze the root causes of the problem or process.

-

Improve the process by implementing counter-measures.

-

Control the performance by putting in place control mechanism to monitor and sustain new level of improvement.

DMADV stands for:

-

Define the goals of the design activity that are consistent with customer demands and enterprise strategy.

-

Define the goals of the design activity that are consistent with customer demands and enterprise strategy.

-

Measure and identify CTQs (critical to qualities), product capabilities, production process capability, and risk assessments.

-

Analyze the design alternatives, develop high-level design and evaluate design capability to select the best design.

-

Design details, optimize the design, and plan for design verification. This phase may require simulations.

-

Verify the design, set up pilot runs, implement production process and handover to process owners.

At its core, Six Sigma revolves around a few key concepts as follow:

-

Critical to Quality: Attributes most important to the customer.

-

Defect: Failing to deliver what the customer wants.

-

Process Capability: What your process can deliver.

-

Variation: What the customer sees and feels.

-

Stable Operations: Ensuring consistent, predictable processes to improve what customer sees and feels.

-

Design for Six Sigma: Designing to meet customer needs and process capability.

Lean Six Sigma

Lean Six Sigma for services is a business improvement methodology that maximizes shareholder value by achieving the fastest rate of improvement in customer satisfaction, cost, quality, process speed, and invested capital. But how actually does Six Sigma and Lean complement one another?

For Six Sigma, it:

-

Emphasizes the need to recognize opportunities and eliminate defects as defined by customers.

-

Recognizes that variation hinders our ability to reliably deliver high quality services.

-

Requires data driven decisions and incorporates a comprehensive set of quality and analytical tools under a powerful framework for effective problem solving.

-

Promises and delivers over $500,000 of improved operating profit per Black Belt per year, when implemented correctly (a target many companies consistently achieved).

For Lean, it:

-

Focuses on maximizing process velocity.

-

Provides tools for analyzing process flow and delay times at each activity in a process.

-

Emphasizes on the separation of "value-added" from "non-value-added" work or 'wastes' with tools to eliminate the root causes of non-valued activities and their cost, for example, the 7 Wastes.

The key concepts of a Lean Enterprise center on 5 principles:

-

Value: A product and/or service defined by the Customer.

-

Value Stream: All actions to bring a product and/or service to the customer.

-

Flow: How the value stream actions work together.

-

Pull: Provide value when the customer asks for it.

-

Perfection: Focus on the customer and eliminate waste.

The fusion of Lean and Six Sigma improvement methods is required because:

-

Lean alone cannot bring a process under statistical control.

-

Six Sigma alone cannot dramatically improve process speed or reduce invested capital.

-

Both enable the reduction of the cost of complexity.

The two methodologies interact and reinforce one another, such that percentage gains in Return on Investment (ROI) are much faster if Lean and Six Sigma are implemented together. In short, what sets Lean Six Sigma apart from its individual components is the recognition that you cannot do "just product/service quality" or "just process velocity," but you need a balanced process that can help an organization focus on improving service quality, as defined by the customer within a set time limit.

Six Sigma identifies five key roles for its successful implementation.

-

Executive Leadership includes CEO and other key top management team members. They are responsible for setting up a vision for Six Sigma implementation. They also empower the other role holders with the freedom and resources to explore new ideas for breakthrough improvements.

-

Champions are responsible for the Six Sigma implementation across the organization in an integrated manner. The Executive Leadership draws them from the upper management. Champions act as mentor to Black Belts.

-

Master Black Belts, identified by champions, act as in-house expert coach for the organization on Six Sigma. They devote 100% of their time to Six Sigma. They assist champions and guide Black Belts and Green Belts. Apart from the usual rigor of statistics, their time is spent on ensuring integrated deployment of Six Sigma across various functions and departments.

-

Experts work across company boundaries, improving services, processes, and products for their suppliers, and for their customers. Experts work not only across multiple sites, but can be also across business divisions, incorporating lessons learned throughout the company.

-

Black Belts operate under Master Black Belts to apply Six Sigma methodology to specific projects. They devote 100% of their time to Six Sigma. They primarily focus on Six Sigma project execution, whereas Champions and Master Black Belts focus on identifying projects/functions for Six Sigma.

-

Green Belts are the employees who take up Six Sigma implementation along with their other job responsibilities. They operate under the guidance of Black Belts and support them in achieving the overall results.

You can find from the history of Six Sigma that many organizations, service industry and government departments, had used the model to leverage huge performance improvements and billions dollars in cost savings. None of them happens on its own but require trained teams and team leaders to cohesively implement Six Sigma processes - especially the use of the measurement and improvement tools, and in communication skills, necessary to serve the needs of internal and external customers and suppliers that form the critical processes of the organization's values stream. Success or failure of a project also depends on the careful selection and application of right tools. From next section onwards, I will focus solely on the tools that are used in the Six Sigma model.

Activity Network

It is one of the QFD's 7 core tools, used in project planning for connecting together a multi-task complex set of interdependent activities. The Activity Network is sometimes called an Arrow Diagram or PERT Chart, where PERT stands for Programmed Evaluation Review Technique. It allows you to calculate what task to start when, the earliest start date and find quicker ways to work around dates, what float there in the project, and to address risks to completing a project on time. We usually use Project Management software programs to work with Activity Networks. The programs perform the critical path calculation, along with other tasks such as leveling and cost calculations.

See this flow-structure of an Activity Network diagram. A project is composed of a set of actions or tasks which usually have some kind of complex interdependency, and Activity Network flow diagram explain such interconnections much better through words. The diagram explains about predecessor tasks and successor tasks, and the points where arrows meet are called nodes. Because there are tasks/activities at these points, it is also known as an Activity-on-Node Diagram. It is usually easier to work with than the alternative Activity-on-Arrow Diagram, where the arrows represent tasks, where we use Critical Path Method (or CPM) to calculate the time required to complete each task. Once the start date for the overall project is known, CPM can provide the earliest and latest start dates for each task.

The amount of time that a task can be delayed without affecting the completion time of the overall project is known as the Slack Time or Float. Slack can either be regarded as a 'safety margin'. The total of all slack times for all tasks in the project gives the total 'time wasted', and may be reduced if the tasks can be rearranged. When people and resources are allocated to tasks, it may also be necessary to rearrange tasks so that people do not have to work overtime to work on more than one task at once. This is called 'leveling' or 'resource smoothing'. The critical path through the activity network is the sequence of tasks which have zero slack time. Thus, if any task on the critical path finishes late, then the whole project will also finish late. See this second diagram that explains Critical Path and Slack Time.

There could be situation of a task or activity which takes no time to complete. This is called a 'checkpoint' or 'milestone', and is usually included in the diagram to highlight an important point in the project. The Activity Network can be used to identify risk in the plan.

Below are typical areas where risk of the schedule being slipped are imminent. [ Click ] to see this diagram.

-

Anywhere on the critical path.

-

Where a task has many predecessors, and if any one predecessor task is delayed, then the task will also be delayed.

-

Where there is a long sequence of tasks, each with a single predecessor and successor. If any task is delayed, it will delay all of its successor tasks. Also, a small risk of delay for each task adds up to a large delay for the overall task sequence.

-

When a resource or person that may become unavailable is used in any of the above situations, the risk is compounded.

-

Where there are several risky tasks running at one time, there are danger of a simultaneous failure.

Below are steps that show how to construct an Activity Network.

-

First Define the key objective of the plan.

-

Identify constraints (time, cost, etc) which may affect the actual tasks.

-

Identify the actual tasks that need to be done. (you can start with a Tree Diagram, but only the bottom-level tasks will be used in the Activity Network).

-

For each task identified, determine the time that each task will take, and write out their earliest start and finish dates, and their latest start and finish dates.

-

Identify the tools, resources, etc required for each task, including the person's name if is already known.

-

Start from the beginning, write out which tasks must be done first, second... until all the last tasks.

-

Arrange the sequence of start of the tasks into a spreadsheet, starting from the first left column.

-

Draw out the task boxes in their start sequence and connect them by arrowed lines.

-

Starting with the tasks at the beginning of the diagram, write the early start and early finish for each task in turn, following the arrows to the next task. [ Click ] to see the explanation in this diagram.

(Note: the early start of a task is the same as the early finish of the preceding task. If there is more than one predecessor task, then there are several possible early start figures; select the largest of these. The early finish for each task is simply the early start plus the duration of the task).

Starting with the tasks at the end of the diagram, complete the late start and late finish for each task in turn, following the arrows in the reverse direction to the previous task. [ Click ] in this diagram to see the explanation on calculating backward.

(Note: a task cannot be completed until all of its successors have been completed. The late finish is the same as the late start of the succeeding task. For the final tasks in the project, this is equal to the earliest completion date, calculated in step 9. If there is more than one successor task, then there are several possible late figures; select the smallest of these. The late start for each task is simply the late finish minus the duration of the task).

Calculate the slack time for each task as the difference between the early and late times. Also identify the route through the diagram where the slack time on each task through the route is zero. This is called the critical path, as any slippage in these tasks will affect the overall project completion date. [ Click ] in this diagram to see how float is calculated.

Check that the plan meet all the constraints you had identified, and and act upon the results. Your actions may include:

-

Reducing the total slack in the project by rearranging tasks.

-

Preventing people from having to work overtime, reallocation and task rearrangement.

-

Identifying risky parts of the plan and reducing risks by reallocation or rearrangement.

-

Recalculating the early and late times to find the effect of the above actions on the critical path, the project completion time and the slack.

Begin tasks, use the activity diagram to help manage your project. Management actions may include:

-

Substituting actual durations of tasks into the diagram.

-

Re-estimating future task durations, using known task durations.

-

Adding, modifying or removing tasks.

-

Rearranging the resources used.

-

Recalculating the early and late Start and Finish times to find the effect of the above actions.

Affinity Diagram

Affinity Diagram (sometimes referred to as a "KJ", after the initials of the person who created this technique, Jiro Kawakita) is a brainstorming tool that is used to gather large amounts of ideas, opinions, or issues and group those items that are naturally related, and identify, for each grouping, a single concept that ties the group together.

An Affinity Diagram is especially useful in situations when:

-

The team is drowning in a large volume of ideas

-

New pattern of thinking is required

-

Broad issues or themes must be identified

-

Building an Affinity Diagram is a creative rather than a logical process that encourages participation and to draw everyone's ideas into the exercise.

For a given project in the view of project management there are essentially five phases:

-

Develop header and ideas

-

Display the ideas

-

Re-group headers and ideas

-

Create header cards

-

Build the Affinity Diagram

A header is an idea, a Phrase or sentence that captures the essential link among the ideas contained in a group of cards. Attached is an example of a 5 steps Affinity Diagram.

Cause and Effects Analysis

The cause and effect diagram (or sometimes called Ishikawa or fishbone diagram) illustrates the main causes and sub-causes (fishbones) that are believed to lead to the effect (head of the fish) being studied. The fishbone diagram identifies many possible causes for an effect or problem. It can be used to structure a brainstorming session. Using this process, it immediately sorts ideas into useful categories. The main categories are often selected as Methods, Equipment, Personnel, Materials, but other categories may be selected as appropriate (suppliers, operations, sales, customers, etc). It is important to identify the main causes or MPC (most probable causes) of the problem which can save the project team a lot of time.

5-why’s

The 5 Whys is a simple problem-solving technique that helps users to get to the root of the problem quickly. Made popular in the 1970s by the Toyota Production System, the 5 Whys strategy involves looking at any problem and asking: "Why?" and "What caused this problem?" Very often, the answer to the first "why" will prompt another "why" and the answer to the second "why" uncover another "why" and so on; hence the name the 5 Whys strategy. By asking the question "Why" we can separate the symptoms from the causes of a problem. This is critical as symptoms often mask the causes of problems. To visually view the process of the “5-why’s”, a fishbone diagram is often helpful. A good rule is that there is not typically one root cause for a problem, but potentially several. 5 Whys plays a part in the Deming Plan Do Check Act (PDCA) cycle and Isikawa root-cause analysis as well.

Following is an example of the 5 Whys analysis as a problem-solving technique:

1. Why did the robot stop? Because the circuit has overloaded, causing a fuse to blow.

2. Why is the circuit overloaded? Because there was insufficient lubrication on the bearings, so they locked up. 3. Why was there insufficient lubrication on the bearings? Because oil pump wasn't circulating sufficient oil.

4. Why is the pump not circulating sufficient oil? Because the pump intake is clogged with metal shavings.

5. Why is the intake clogged with metal shavings? Because there is no filter on the pump.

6. Why is there no filter on the pump? Because it is a revised design of the pump.

7. Why were there metal shavings in the pump? Because the modified design failed to capture them.

8. Why do they need to modify the design? Because it was our cost reduction program request.

9. Why did we have a cost reduction program on a critical robot function? Because........

The Whys continue on. As you can see, the 5 Whys can help you uncover root causes quickly. One common problem often happened in using 5 Whys is that people falling back on guesswork. Making a single mistake in any question or answer can produce false or misleading results.

CTQ Tree

A CTQ tree (Critical-To-Quality tree) is used to decompose broad customer requirements into more easily quantified requirements. It sets out the measurable elements of a process that are critical to achieving customer quality and satisfaction. In one way, it also helps the project team to move from high-level requirement to detail specifications while ensuring that all aspects of customer's need are identified and fully aligned.

The CTQ measures are designed to ensure that company's process improvement and innovation projects are fully aligned with those areas that are most valued by customers. The upper and lower specification limits must be set on each CTQ measure to ensure that the product or process conforms to the standards required by the customers. A CTQ tree usually must be interpreted from a qualitative customer statement to an actionable, quantitative business specification. This process involves identifying the VOC and then establishing CTQ measures. You can expand the CTQ measures to level 3, 4 or more as required.

Here is an example of a 2-levels CTQ-Tree Diagram.

Day-In-The-Life Analysis

A Day-In-The-Life study is used to analyze the current jobs for non-value-added activities, and describe the future activities of a job when planned changes have been implemented. To develop a study on a person's job or duties, use the following steps.

-

Identify the job and role to be reviewed.

-

Confirm the job description and the purpose of the role.

-

List the key performance objectives for the role.

-

List the timing and activities performed on a regular day basis.

-

Assess how much each activity contribute towards the objectives at the end of day.

-

Make comments where there are concerns.

-

Asses the overall status for each activity by assigning symbol signs.

-

Summarize the % of time in each category (by symbol signs).

As people often resist any analysis of how they spend their time daily and productively, you should therefore insist to focus on the non-value added activities that you want to eliminate but which they try to avoid.

[ Click ] See an employee example of a Day-In-The-Life study.

Force Field Analysis

Force Field Analysis is a qualitative analytical tool that is designed to show the positive and negative forces impacting a change within an organization. The positive or driving forces (forces that favor change) are represented as pushing against the negative or restraining forces (forces that impede change). In effect, it is a specialized method of weighing pros and cons. By carrying out the analysis you can plan to strengthen the forces supporting a decision, and reduce the impact of opposition to it.

You can easily create a template in the spreadsheet like the one I have shown below. First, describe your plan or proposal for change in the middle column. Then list all the forces for change on the left column, and all the forces against the change on the right column. Finally assign a score to each force, from -5 (weakeast) to 5 (strongest). Once you have carried out an analysis, you can decide whether your project is viable. If you have already decided to carry out a project, Force Field Analysis can help you to work out how to improve its probability of success. There are two ways - to reduce the strength of the forces opposing a project, or to increase the forces pushing a project. Often the most elegant solution is the first choice as just trying to force change through may cause its own problems.